The following information

has been reproduced from a post

to a thread on idle instability

issues on skylinesdownunder.co.nz

forums by 'phantom'. All credit

for this information goes to 'phantom'

and thanks for his permission to

reproduce here.

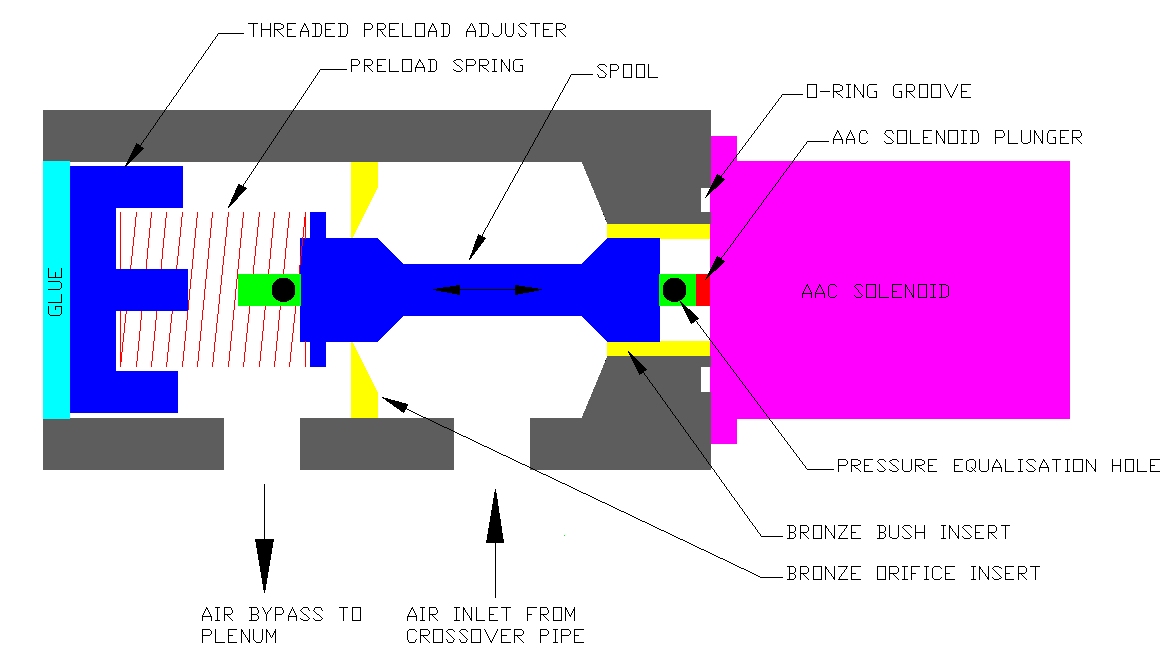

I'm having some technical

difficulties with my digital camera,

in particular focusing at close

distances! As such my attempts to

get a descent view of the AAC spool

etc. wasn't to good. I have instead

done an auto cad drawing of the

R33 AAC valve. Bear in mind that

this is a basic drawing for conceptual

purposes only!! It will however

give you a good understanding on

how it works. Additionally I've

also drawn a representation of my

new spool.

|

What

does it look like?

- AAC Valve |

|

| |

|

|

|

|

|

As states this drawing is a conceptual

interpretation of the inner workings

of the AAC and spool. The point

of wear on these things occurs on

the bronze bush insert on the right

and the bronze orifice insert on

the left. A loose spring will not

pre load the spool at all and it

will probably float around causing

irregular idle conditions. When

wear has occurred leakage through

the bronze orifice ensues even before

the taper section of the spool is

exposed.

This results in an AAC without a

significant airflow difference between

open and closed and anywhere in

between. Additionally, wear in the

bronze bush on the right causes

air to be sucked through the air

supply side, into the cavity enclosed

by the spool and the solenoid, and,

subsequently through the pressure

equalisation hole in the spool all

the way through to the other side

of the orifice and into the engine.

This leakage bypasses the spool

altogether. The spool has a hollow

steel tube at the centre to support

and guide everything.

The reason for it being hollow and

having a hole on each side is to

equalise the pressure on both sides

of the spool such that pressure

differences occurring as a result

of general engine running don't

cause the spool to move. Movement

can only be caused by the solenoid

plunger movement. This is typical

of this type of valve and I have

seen similar pressure equalisation

techniques in industrial hydraulic

and pneumatic proportional valves.

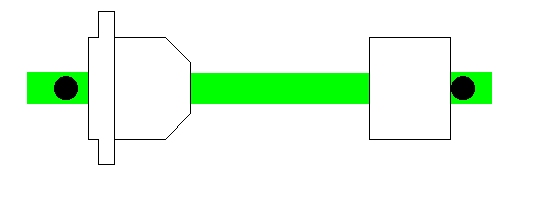

As the bush and orifice would be

difficult to manufacture I did the

next best thing and made a new spool

instead. I placed the spool in a

lathe and VERY GENTLY machined off

the plastic leaving the hollow central

tube. I then made the replacement

in three sections, purely out of

the difficulty in making such small

components with the size of cutting

tools I had available. The spring

retainer is straightforward and

can be very approximate in its sizing.

The taper section was then turned

down to a diameter measured with

an inside micrometer on the bronze

orifice hole. I made it slightly

larger and polished it to size whilst

in the lathe with some emery until

it JUST slid into the orifice without

binding. This took a few attempts

to get right. The bush end does

not need to have the taper as per

the factory. This is probably just

a manufacturing simplification.

It was simply a cylindrical section,

again referenced to the measurement

of the existing bush diameter as

measured with the inside micrometer.

I actually made it slightly longer

than standard as far as the equalisation

hole allowed on that side. The reason

being that the additional length

would assist in alignment once inserted

into the bush, and stop the tendency

for vibration to cause further wear.

All the sections had a 4 mm diameter

axially drilled hole on the lathe.

Accuracy is highly important, as

with close tolerances misalignment

will lead to the spool binding in

operation. I then slid the three

sections over the hollow tube, carefully

positioning the taper to the same

position as the original. The cylindrical

side placement was not as critical,

and simply slid far enough up to

the equalisation hole. I secured

these onto the hollow tube with

super glue. Don't laugh, but super

glue is designed for very close

fitting surfaces, and since the

4mm hole in the sections made a

nice sliding fit over the tube,

the super glue worked fantastically.

Placing the new spool back into

the body and blocking the relevant

holes then blowing through it revealed

almost zero leakage when closed.

Only once the spool was moved over

exposing the taper did significant

flow occur....just what the doctor

ordered!!

|

What

does it look like?

- Spool |

|

| |

|

|

|

|

|

Next a new spring was found and

chopped and reshaped to the original

length but significantly lighter.

I wanted to maximise the movement

of the spool with the solenoid force

to amplify its effect on engine

RPM. As stated in the past the pre

load spring retainer is threaded

into the body and its depth can

be adjusted by turning the retainer.

The glue applied by the factory

over this was simply milled through

on a milling machine until I just

contacted the retainer. I then picked

out the remaining glue in the retainer

phillips head with a scriber. This

then allowed me to get a wide flat

blade screwdriver onto the retainer

and screw it out. The indentation

on the retainer is not exactly a

philips head but really a cross

with a circular centre. The factory

obviously has an automated tool

used for manufacturer adjustment

prior to glue sealing.

Once back together and on the car,

the engine was started and allowed

to reach temperature. I set the

RPM manually via the idle screw

to approximately 650 rpm so as to

not cause the solenoid to push out

the spool trying to compensate.

I then unscrewed the retainer until

the engine RPM JUST started to increase,

then turned it back in about a quarter

turn. This ensured that with the

given base duty cycle on the solenoid,

the resulting force had the spool

JUST about expose the taper. This

would guarantee that any further

increase in duty cycle by the ECU

would immediately expose the taper

and increase RPM rather than being

wasted just sliding the spool whilst

still on the straight portion in

the orifice.

As I've stated, once this was done,

the idle control returned with a

vengeance...and has been operating

beautifully now for about two weeks

straight. I resealed the pre load

adjuster with some silicone, as

there is slight leakage through

the thread. The silicone can be

easily pried out in future should

I need to readjust or disassemble.

Some may wonder why I bothered

with this. Well, this cost me nothing...a

new AAC costs $650. In addition

I had the advantage of adjustability

and therefore tunability to my specific

engine. A brand new one would remain

unadjustable.

Information

derived from 'phantom' at skylinesdownunder.co.nz

Information

on the page was last updated 10

July 2003

|